Top Selling Products

Reviews & Ratings

0

out of 5.0

(0

reviews)

There have been no reviews for this product yet.

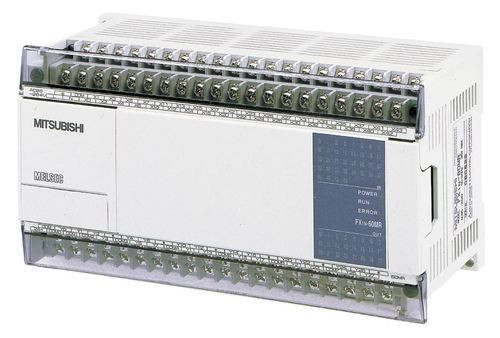

MITSUBISHI FX1N-60MR-DS Product information and technical parameters:

Brand: MITSUBISHI

Name: PLC

Model: FX1N-60MR-DS

Max input / output points: 60 points.

Power supply voltage: 12-24VDC.

Input points: 36 points.

Output points: 24 points.

Output type: relay.

Power consumption (W): 20.

Weight (kg):0.8.

Size (WxHxD) mm:175x90x75.

Terminal row type standard machine with extended input output

Can also be less of a system with analog or communication, etc..

CPU, power supply, input and output integration.

Display module or function expansion board can be less installed.

In addition, you can also reduce the input output or special module.

Built in 8000 step EPROM memory.

No battery. Maintenance free.

Overseas oriented products meet all kinds of international standards.

FX1N series is a very powerful micro PLC, can be extended to up to 128 I/O points,

And can increase the special function module or the expansion board.

Communication and data link function options make FX1N in the volume, communication and special function modules and other important applications is very perfect.

A PLC unit can output 2 100KHz pulses at the same time,

PLC is equipped with 7 special positioning instructions,

Including zero return, absolute position readout, absolute or relative drive, and special pulse output control.

Brand: MITSUBISHI

Name: PLC

Model: FX1N-60MR-DS

Max input / output points: 60 points.

Power supply voltage: 12-24VDC.

Input points: 36 points.

Output points: 24 points.

Output type: relay.

Power consumption (W): 20.

Weight (kg):0.8.

Size (WxHxD) mm:175x90x75.

Terminal row type standard machine with extended input output

Can also be less of a system with analog or communication, etc..

CPU, power supply, input and output integration.

Display module or function expansion board can be less installed.

In addition, you can also reduce the input output or special module.

Built in 8000 step EPROM memory.

No battery. Maintenance free.

Overseas oriented products meet all kinds of international standards.

FX1N series is a very powerful micro PLC, can be extended to up to 128 I/O points,

And can increase the special function module or the expansion board.

Communication and data link function options make FX1N in the volume, communication and special function modules and other important applications is very perfect.

A PLC unit can output 2 100KHz pulses at the same time,

PLC is equipped with 7 special positioning instructions,

Including zero return, absolute position readout, absolute or relative drive, and special pulse output control.

Input points: 8 points.

Output points: 6 points.

Power supply voltage: AC100-240V.

Output type: relay output.

Built in CPU, power supply, input and output. While maintaining the convenience of FX1N while improving performance.

Special adaptor and function expansion board can be installed and used FX3 series MITSUBISHI FX1N-60MR-DS.

High speed operation.

Basic instructions: 0.21 s/ instruction.

Application instruction: 0 FX1N-60MR-DS5 s/ instruction.

Large capacity memory.

Built in program memory 32000 steps.

EEPROM memory cartridge with program transfer function. Function: terminal row input.

Input points: 16 points.

Connected programmable logic controller: FX1NC, FX2NC, FX3UC.

Weight: 0.15KG.

FX2NC expansion module can be directly connected to the FX1NC, FX2NC, PLC FX3UC on the expansion of the input and output MITSUBISHI FX1N-60MR-DS.

Do not need to connect the cable and so on, therefore can carry on the compact expansion. Max input / output points: 14 points.

Power supply voltage: 24VDC.

Input points: 8 points.

Output points: 6 points.

Output type: relay.

Power consumption (W): 6.5.

Weight (kg):0.22.

Size (WxHxD) mm:60x90x49.

Host has 10 points (6I/4O), 14 points (8I/6O), 20 points (12I/8O), 30 points (16I/14O) of 4 types MITSUBISHI FX1N-60MR-DS.

This type of PLC is mainly used in all of the digital input, digital output control point of the device.

Can be directly connected to the 220V city power, built-in 8K step EEPROM memory, no battery, easy to maintain.

The series transistor output (MT) of the PLC, can be output 2 100KHz pulse, direct drive servo or stepper motor.

The series PLC can not be brought with the expansion module, but can be installed by the BD board to extend a small amount of I/O.

The series 1N tthrough the installation of BD series PLC board, can achieve RS232, RS485, RS422 communication FX1N-60MR-DS.

All equipment is digital input and output point.

The total I/O points are not more than 30 points, and the input points are less than 16, thhe output points are less than 14 FX1N-60MR-DS.

Its MT series of PLC can drive 2 way servo or stepper, commonly used in the control system for a simple manipulator.

Output points: 6 points.

Power supply voltage: AC100-240V.

Output type: relay output.

Built in CPU, power supply, input and output. While maintaining the convenience of FX1N while improving performance.

Special adaptor and function expansion board can be installed and used FX3 series MITSUBISHI FX1N-60MR-DS.

High speed operation.

Basic instructions: 0.21 s/ instruction.

Application instruction: 0 FX1N-60MR-DS5 s/ instruction.

Large capacity memory.

Built in program memory 32000 steps.

EEPROM memory cartridge with program transfer function. Function: terminal row input.

Input points: 16 points.

Connected programmable logic controller: FX1NC, FX2NC, FX3UC.

Weight: 0.15KG.

FX2NC expansion module can be directly connected to the FX1NC, FX2NC, PLC FX3UC on the expansion of the input and output MITSUBISHI FX1N-60MR-DS.

Do not need to connect the cable and so on, therefore can carry on the compact expansion. Max input / output points: 14 points.

Power supply voltage: 24VDC.

Input points: 8 points.

Output points: 6 points.

Output type: relay.

Power consumption (W): 6.5.

Weight (kg):0.22.

Size (WxHxD) mm:60x90x49.

Host has 10 points (6I/4O), 14 points (8I/6O), 20 points (12I/8O), 30 points (16I/14O) of 4 types MITSUBISHI FX1N-60MR-DS.

This type of PLC is mainly used in all of the digital input, digital output control point of the device.

Can be directly connected to the 220V city power, built-in 8K step EEPROM memory, no battery, easy to maintain.

The series transistor output (MT) of the PLC, can be output 2 100KHz pulse, direct drive servo or stepper motor.

The series PLC can not be brought with the expansion module, but can be installed by the BD board to extend a small amount of I/O.

The series 1N tthrough the installation of BD series PLC board, can achieve RS232, RS485, RS422 communication FX1N-60MR-DS.

All equipment is digital input and output point.

The total I/O points are not more than 30 points, and the input points are less than 16, thhe output points are less than 14 FX1N-60MR-DS.

Its MT series of PLC can drive 2 way servo or stepper, commonly used in the control system for a simple manipulator.

Related Product

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

Top Selling Products